Carburetter Replacement Veritas-Nürburgring from 2x H4 standard to 3x H2 to increase hp

Veritas-Nürburgring

Veritas Nürburgring 1953 (Foto:Wikipedia/Stahlkocher)

Veritas Nürburgring 1953 (Foto:Wikipedia/Stahlkocher)

Motor Tuning

Veritas-Nürburgring Logo

Veritas-Nürburgring Logo

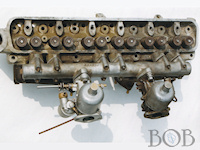

A completely new aluminium cylinder-head with larger inlet-valves, two three-into-one exhaust manifolds and a one-piece inlet-manifold with two SU H4 cross-draught carbs (1,5 inch) were developed. This gave the engine a surprising 105 hp.

Inefficient Gas-Flow

Here you can see the really inefficient gas-flow - the first and sixth cylinder were very badly fed. Sports-cars of the 30´s era also had a similar problem.

The only reasonable method to solve this problem was to convert the whole induction system to three separate carbs. The three more or less separate inlet ducts, each feeding two cylinders were ideal for this task.

The only reasonable method to solve this problem was to convert the whole induction system to three separate carbs. The three more or less separate inlet ducts, each feeding two cylinders were ideal for this task.

Support Jig

The three inlet tracts were separated and new flanges for the carbs turned up. The inlet tracts were drilled horizontally and a jig made up to support all the parts as they were being welded. Three short, stubby tubes were also turned up as a base for the vacuum line.

Calculations

To achieve optimal flow rates, H2 carbs were chosen. They have 1,25inch diameter ducts and the three of them have approximately the same throat diameter as two H4s – see following formula:

The approximately 12% larger passage area is balanced by the constant-pressure operation of this carburetter series.

| Original Carburetter 2x H4 | Replacement Carburetter 3x H2 | |

|---|---|---|

| diameter | d=25,4mm/“ x 1,5“ = 36,75mm | d=25,4mm/“ x 1,25“ = 31,75mm |

| radius | r=d/2=36,75mm/2 = 18,37mm | r=d/2=31,7mm/2=15,87mm |

| duct flowarea | A=πr²= 1059,61mm² | A=πr² = 790,83mm² |

| flowarea | D=1059,61mm² x 2 = 2119,22mm² | D=790,83mm² x 3 = 2372,49mm² |

| Compare | 100% | 2372,49mm²/2119,22mm²*100%=111,95% |

The approximately 12% larger passage area is balanced by the constant-pressure operation of this carburetter series.

Welding

After final welding, the parts were fettled to shape and end-caps turned and also welded into place.

Finally the whole cylinder-head with the newly modified inlet-manifolds, were attached to a milling machine and the face-surfaces of the carbs were milled vertically. Aluminium tends to warp quite a lot during heat-treatment/welding and the jig could not garantee a plane surface. A vacuum line was produced out of copper piping with an extra outlet for the brake servo-unit and secured to the separate manifolds using turned, brass fittings. Finally choke- rods and throttle linkages were produced and fitted.

Finally the whole cylinder-head with the newly modified inlet-manifolds, were attached to a milling machine and the face-surfaces of the carbs were milled vertically. Aluminium tends to warp quite a lot during heat-treatment/welding and the jig could not garantee a plane surface. A vacuum line was produced out of copper piping with an extra outlet for the brake servo-unit and secured to the separate manifolds using turned, brass fittings. Finally choke- rods and throttle linkages were produced and fitted.

Result

After several test-runs using various needles, the optimal mixture was achieved and smooth-running was the outcome with an estimated 115-120hp, nearly double that of the original, no doubt due to the extremely good gas-flow as the inlet-manifolds are basically directly in front of the inlet ducts.

Δ Back to Top

©2013 by Automobilmanufaktur Kassel | Vintage Carburetter Restoration | Fon 0561-8906812 | Contact

Last actualisation: 02.07.2013

Last actualisation: 02.07.2013

English

English Carburetter replacement

Carburetter replacement Publications

Publications Timetable

Timetable References

References Links

Links Pricelist

Pricelist Archive

Archive Tuning Information

Tuning Information SU

SU  DB 190SL

DB 190SL Porsche

Porsche Electric

Electric Air Valve Bds.

Air Valve Bds. Reproduction

Reproduction That's me

That's me Workshopcam

Workshopcam Fun

Fun Contact

Contact Roadmap

Roadmap Terms of Trd.

Terms of Trd. Import/Export

Import/Export Impressum

Impressum